Do you want to know how a spa, or what is also popularly referred to as an outdoor jacuzzi, is manufactured?

In this article we will explain step by step each of the manufacturing processes of a premium quality spa, in the only spa factory in Europe, specifically in Spain.

Manufacturing processes of a jacuzzi

Navegación rápida

Most likely, if you are thinking about buying a spa, this article about the most important steps of its manufacture will be very interesting for you. Here you can see all the manufacturing processes so you can understand how we take relaxation to your home!

Thermoforming of a spa’s shell

The first process is the most extraordinary and the most decisive for you! Why? Because you have to choose the colour of the sheet and the model of the spa well, where are going to relax every day.

You cannot imagine how impressive the process of making a spa is, from the first movement of creating the sheet to the final packing.

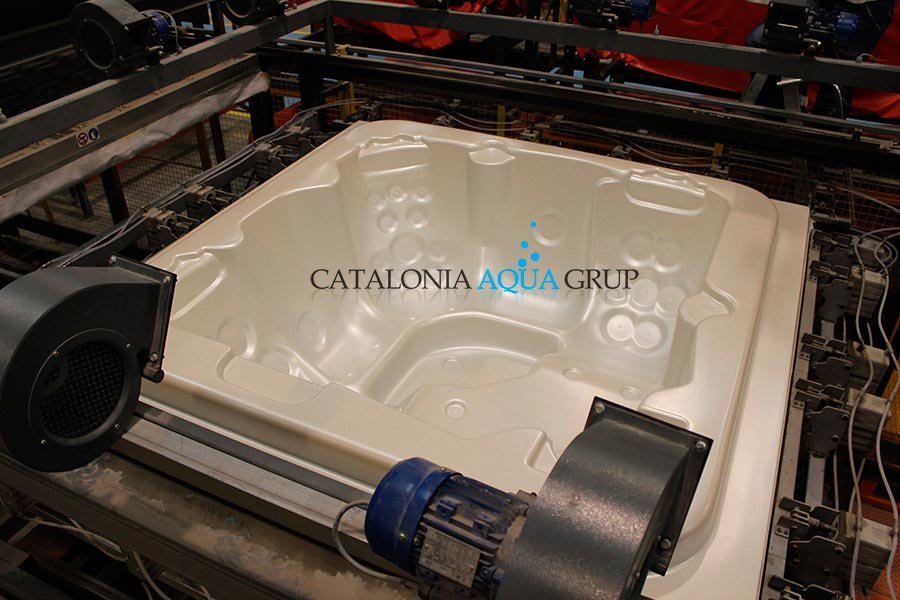

Thermoforming process that will shape the spa’s acrylic

The first step is the moment when the thermoforming machine shapes the sheet that will later become an indoor or outdoor jacuzzi. Defining the different positions of the spa, the sheet is heated and when it reaches the ideal temperature it copies the shape of the selected model, in an amazing way.

Important: There is no turning back! we have the chosen model and the colour of the shell defined

Spas with reinforced sheet

The comfort of our spas is thanks to its sheet!

Here you can see the projection of the jacuzzis, so you will see a process of how the sheet is reinforced. The first piece we see is a piece just a few millimetres thick which is thin and flexible. At that moment you ask yourself if something so thin can really hold my body and a thousand litres of water? But yes, thanks to a projection of resin and fibre the shell is reinforced to be able to support all this weight.

Modelling the spa shell with fibreglass

You will ask yourself how we can guarantee what we are telling you about because we fully trust our processes and therefore, we offer you an exceptional warranty.

Look!

- 15-year structure warranty.

- 10-year acrylic warranty.

- 2-year component warranty.

We manufacture our jacuzzis manually in a careful process supervised by the workers of our team in the same way that our spa will end up taking care of you and your loved ones.

Automatic cutting system to guarantee the sealing of the spa

Accuracy is important: When it is a jacuzzi that has to withstand the pressure of more than a thousand litres of water inside one of the points that most concerns us is to ensure its sealing.

Digital machining of each of the perforations of the spa jets

To ensure that there are no leaks in the different accessories that are assembled in a spa we have a cutting-edge machining centre that not only makes all the holes needed to install the hot tub jets but also gives an ideal finish to ensure the sealing of the shell.

Assembling the accessories in our jacuzzis

The manufacturing process of our spas is carried out with the innovative LEAN Manufacturing system:

Do you know what Lean manufacturing is? Here you can find out what it is!

Watertight sealing of each of the joints of our spa

ean Manufacturing is a simple, profound and effective work methodology that originated in Japan focused on increasing productive efficiency in all processes from which the Kaizen management philosophy is implemented for continuous improvement in time, space, waste, inventory and defects involving the worker and generating in the worker a sense of belonging to be able to participate in the process of proposing his/her ideas on how to do things better.

Our spa factory

The first sensation you will have when you see the photograph of our spa factory is of order. The fact is that for us the order is a very important factor to be able to work efficiently.

The process of assembling the accessories of the spa is surprising because it has different stages: first, the pre-assemblies of each of the accessories are made; then all these elements are coupled in the spa according to their serial number and finally the electrical equipment (motors, heating, electrical panel …) are mounted in the model.

Spa manufacturing and assembly area

Spa by spa quality test

This is the definitive test that assures us the reliability of our spas.

It is a testing process so that the customer can enjoy the spa carefree.

We perform two different tests: a hydraulic test and an electrical test. Each of the spa’s components and correct operation according to the ex-works protocols are checked.

Quality test to guarantee each of our spas

A test to trust the warranty of our spas!

Installing the cabinet in the spas

One of the last manufacturing processes before packing that will leave your spa ready to send to your house.

The last process before packing the spa involves assembling the wood panels. It is in this step that the extra thermal insulation is included to create an air chamber inside the jacuzzi and achieve a great saving in energy consumption: your wallet will thank you!

Placement of the soffits of the spa’s cabinets

A final finish with the brand in stainless steel finish on the unit and … the spa is finished!

Packing a jacuzzi

How will you receive your jacuzzi at home?

This is a good question because once you have bought your spa you will have to handle it to place it in the desired place. The spa comes fully packed with different layers of plastic so that the spa is not damaged. Also in the packaging there are indications such as reference and serial number, very important information that you should also find in the invoice of your product and that will be very useful when sending the warranty with your data to Aquavia spa.

Packaging process of a spa

Now it only remains to install your new spa, fill it with water, heat it up and enjoy the best of hydromassages.